|

上海智尊工业自动化有限公司 |

| |

|

|

|

| 您最信赖的进口备件供应商 |

EBM PAPST

|

依必安派特公司于1963年在德国成立。作为在电机和风机产业领域的技术领导者之一, 依必安派特拥有55家分支机构在世界各地为客户提供专业地风机及电动机的解决方案与服务。 |

|||||||||

Email询价更迅捷: info@zzindustry.net |

|||||||||

|

|||||||||

|

|||||||||

HyBlade With HyBlade |

|||||||||

|

|||||||||

We are taking the next step

The advantages of our large axial fans are really nothing new in the refrigeration and climate control business. After all, ebm-papst has long enjoyed a reputation in this segment for premium quality and premium performance. However, continuously rising requirements in practice demand of us that we never cease to conduct new research into fan technology capabilities. The primary requirements are for the maximum possible airflow rating at the lowest possible noise level. However, the specification profile our developers set themselves also included an optimised efficiency rating, improved corrosion protection, reduced weight and environmentally-aware production with a favourable energy-to-output ratio. For this reason, we are never satisfied with small facelifts or with an evolution of the familiar. For this next stage in development, we are taking a giant |

|

||||||||

step forward. The outcome is genuinely impressive: HyBlade |

|||||||||

HyBlade

|

|||||||||

|

|||||||||

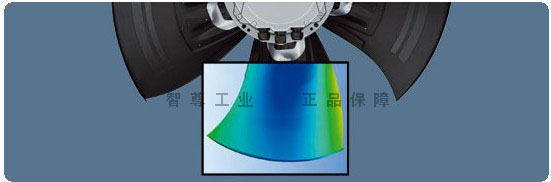

Stability and intelligence to the power of two: HyBlade HyBlade One and one make one Intensive research for improvements in the geometry of the blades of large axial fans has led to a revolutionary new hybrid concept. In the world of technology, "hybrid" always means a combination of different elements. The special feature of this is that even the initial elements can depict a functioning solution. However, only when they are combined do new, positive characteristics emerge from the original benefits. This is where HyBlade The stability of an ultra-strong aluminium alloy inside combined with the lightness and unrestricted malleability of plastic on the outside – that is the ingenious combination which characterises HyBlade First of all, this lightweight mantle initially has a substantial and positive impact on the total weight of the fan, and also helps to reduce noise levels through its favourable damping characteristics. The most important thing however is this: Whereas sheet metal components can only be adapted by means of stamping, bending or embossing, plastics are no problem to turn into three-dimensional shapes. Optimisation of the blade design therefore no longer faces any obstacles – even down to the level of minute detail. Even winglets on the blade tips, of the kind now familiar from motor racing and aircraft design, are now an easy matter to accomplish. These have an aerodynamically favourable effect and minimise turbulence between blade and housing, thereby also enabling the fan to operate even more quietly and with a higher efficiency rating.

|

|||||||||

EC – two letters for energy efficiency EC technology is the key foundation of our energy-efficient motors: on average 30 % less energy consumption, up to 70 % for some applications – that is a word. The controllable drives are bus-compatible and besides saving energy achieve a superb level of efficiency of up to 90 %. In addition, they are completely maintenance-free and have a much longer service life. HyBlade The outstanding characteristics of HyBlade |

|

||||||||

In early 2008, HyBlade |

|||||||||

|

|||||||||

First-class energy balance: HyBlade Our axial fans in HyBlade Power delivered in silence As we see it, environmental protection should also be extended to include noise management. Particularly in the case of large axial fans which are frequent ly found outside buildings, plying their trade inside heat exchangers, it is important to keep noise at an absolute minimum. Here, HyBlade Lightweight for easy handling Another ace in your hand: ease of installation of HyBlade Potential energy saving in terms of raw materials – an example For one, the substantially lower weight of the finished HyBlade The electrical energy input required to generate one kilogram of primary aluminium is approx. 15.4 kWh; this does not even take into account the fuel input (source: "Material efficiency: potential savings during the manufacture and use of energy-intensive raw materials.", German Federal Ministry of Economics and Technology). In contrast to this, one kilogram of plastic (PA6) requires only about 1.8 to 1.9 kWh (source: European Commission JRC, EU dated Oct. 2006). This calculation proves that here at ebm-papst, technical innovation does by no means require additional consumption of resources. On the contrary. Exactly the opposite is true! |

|||||||||

|

|||||||||

Elementary efficiency: HyBlade HyBlade HyBlade As you would expect, every new product at ebm-papst is tested vigorously before it goes into serial production. This is particularly true for a new material compound never seen in the world before and certainly true for our new HyBlade Tested and found to be excellent In addition to long-term fatigue tests and high speeds up to well over three times the maximum operating points, the new hybrid blades are also exposed to water, salt spray fog and chemicals – and able to pass these tests due to their outstanding corrosion resistance. Moreover, the material structure quite literally cannot be shocked when subjected to severe vibration and shock loadings. This ensures that HyBlade |

|||||||||

|

|||||||||

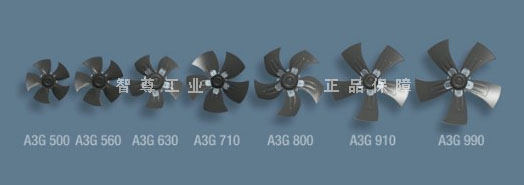

"HyTech" starting at 300 mm: the expanded HyBlade The HyBlade Ideal partners: HyBlade The revolutionary characteristics of the hybrid structure include intelligent controllability, freedom from maintenance, a long service life and the excellent energy efficiency of EC drive technology. HyBlade |

|||||||||

Ebm-Papst Mulfingen GmbH & Co. KG

| 联系我们 | 常见问题 | Copyright@2009 上海智尊工业自动化有限公司 | ||